Craftsmanship That Makes It All Work

It’s not just our equipment that’s top tier; our machinists are skilled and experienced. They know how to run our CNC machines to get the best results.

CNC Machining: High Performance Equipment & Craftsmanship

Our CNC manufacturing capabilities combine hands-on craftsmanship with high-performance equipment. That means we deliver parts that fit, function, and endure. We approach every job with the same level of care: no guesswork, no shortcuts.

We use machines for their capability – from horizontal machining centers to 5-axis vertical mills, each piece of equipment serves a purpose.

- Horizontal Machining Centers excel at heavy material removal and complex multi-sided parts.

- Vertical Machining Centers handle everything from delicate aluminum components to hardened steel.

- 5-Axis Capability means fewer setups and better accuracy for intricate geometries.

Milling and Turning: Where Metal Meets Mastery

When shaping raw material into functional parts, we rely on two powerhouse processes: CNC turning and CNC milling. Both methods remove material to create precision components, but each excels in different scenarios.

CNC Turning: Precision for Cylindrical Parts

In turning, the workpiece spins while a stationary cutting tool carves away material. This method is best for parts like shafts, bushings, and threaded fittings (anything that’s round, tapered, or needs concentricity).

Our turning capabilities include:

- Live tooling: Drill holes, mill flats, or tap threads without removing the part.

- Sub-spindle setups: Complete front and back machining in one go, reducing handling errors.

- High-pressure coolant: Extends tool life and keeps surfaces smooth.

- Tolerances down to ±0.0002″: Because “close enough” isn’t good enough.

A full list of our machinery can be found here, but the equipment below is especially for CNC turning:

- Puma 2500 LY 5-Axis Lathes: Handle complex geometries with Y-axis milling and rigid tapping.

- Puma 240 MSB 4-Axis Sub-Spindle Lathe: Perfect for parts needing backside work.

- Daewoo Puma 12S: A reliable workhorse for high-volume turning.

CNC Milling: Versatility for Complex Shapes

Milling uses rotating cutting tools to shape a stationary workpiece. It’s the go-to for parts with flat surfaces, pockets, or intricate contours.

Why milling?

- Multi-axis machining: 3-axis, 4-axis, and full 5-axis capabilities for complex profiles.

- High-speed spindles: Maintain accuracy even in tough materials like stainless steel.

- Rigid construction: Minimizes vibration for smoother finishes.

Our milling arsenal

- Hyundai-KIA HS630 4-Axis Horizontal Mill: Heavy-duty material removal with 60-tool capacity.

- HAAS VF6 & VF7 Vertical Mills: Geared-head spindles for consistent power.

- Kitamura MyCenter 2: Built for hard metals and demanding tolerances.

Not sure which process you need?

- Turn it if your part is cylindrical or needs threading.

- Mill it if you’ve got flat surfaces, slots, or complex contours.

- Need both? Our lathes with live tooling bridge the gap to reduce setups and improve consistency.

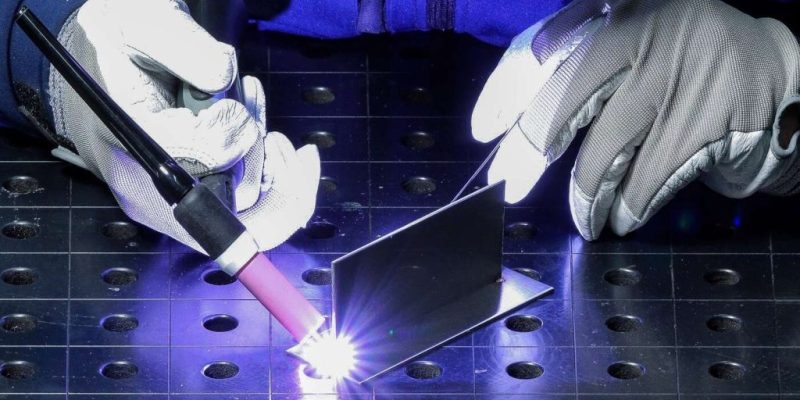

Custom Fabrication & Welding: Building What You Imagine

Some parts can’t be made on a CNC machine alone; they need a welder’s touch. Our fabrication shop combines traditional craftsmanship with modern equipment to create everything from one-off prototypes to full production runs.

What sets us apart

- Hands-on expertise: Nearly 50 years of experience in welding and metalwork.

- Tight tolerances: No sloppy fits or mismatched components.

- Full-service capabilities: Laser cutting, MIG/TIG welding, and CNC machining under one roof.

Equipment we rely on

- Motoman robotic welders: For consistent, high-quality welds.

- Hobart Arc Master 351 Pulse MIG machines: Handle thin gauge up to heavy plate.

- Thermal Dynamics plasma cutter: Slices through 1-inch material with ease.

Finishing: The Final Touch That Lasts

A part isn’t truly done until it’s finished right. We partner with trusted suppliers to apply coatings that protect, enhance or refine your components, making sure they perform as intended, whether in a sterile operating room or a dusty construction site.

Finishing options we offer

- Black oxide: A sleek, corrosion-resistant finish for steel parts.

- Zinc plating: Fights rust while maintaining conductivity.

- Powder coating: Durable, colorful and resistant to chipping.

- Electroless nickel plating: Uniform coverage for complex shapes.

Beyond coatings, we also provide

- Custom assembly: Parts put together before shipping.

- Final inspection: Every piece checked against specs.

- Ready-to-ship packaging: Bulk crates or individual wrapping.

The Auglaize Erie Advantage in Manufacturing

Since 1978, Auglaize Erie has been a trusted name in industrial manufacturing. We don’t just supply equipment, we engineer solutions that keep production lines moving. Our decades of hands-on experience mean we understand the challenges manufacturers face: downtime, equipment wear, and the constant push for greater efficiency.

We design and build machinery that stands up to the toughest demands of the shop floor. No shortcuts, no compromises. Just rugged, reliable equipment engineered to perform. Here’s what sets us apart:

- Experience: Decades of solving tough machining challenges.

- Equipment: Top-tier machines that hold tolerances others can’t.

- No-nonsense quality: We measure, re-measure, and then measure again.

Whether you’re prototyping a new design or scaling up production, we’re ready to put our manufacturing capabilities to work for you.

Let’s build something together. Contact us today to discuss your project.