The Right Tools for the Job

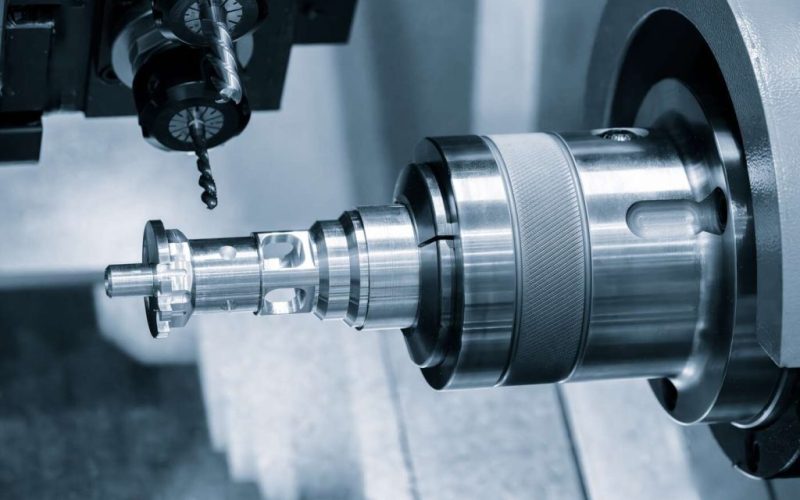

We stock our shop with machines chosen for their capability, not just their brand name. From horizontal machining centers to 5-axis vertical mills, each piece of equipment serves a purpose.

- Horizontal Machining Centers excel at heavy material removal and complex multi-sided parts.

- Vertical Machining Centers handle everything from delicate aluminum components to hardened steel.

- 5-Axis Capability means fewer setups and better accuracy for intricate geometries.

Tolerances That Mean Business

Our machines hold tolerances as tight as ±0.0005″ and we verify every dimension before a part leaves the shop.

More Than Just Button-Pushers

While our CNC equipment is top-tier, it’s our machinists who make the difference. They know how to tweak feeds, speeds, and toolpaths to get the best finish, the longest tool life, and the fastest cycle times without sacrificing quality.

Our CNC Manufacturing Equipment

Horizontal Machining Centers

Hyundai-KIA HS630 4-Axis

- 30 HP spindle, 8000 RPM

- High-pressure through-spindle coolant

- 60-tool capacity

- 41.3″ x 34.4″ x 34.4″ travel

- 360° rotary table (1° increments)

Vertical Machining Centers

HAAS VF6 & VF7

- 20 HP geared-head spindles

- 84″ x 32″ x 30″ travel (VF7)

- Rigid tapping, bolt patterns and complex milling

HAAS DM2 with 5-Axis

- Vertical machining with contouring capability

Kitamura MyCenter 2

- Built for heavy-duty milling

- Exceptional rigidity for tough materials

Materials We Work With

Industries We Serve

The Auglaize Erie Machine Process

1 Understanding Your Needs

We start by reviewing your prints, specs, and performance requirements. If something doesn’t look right, we’ll speak up because catching issues early saves time and money.

2 Material Selection

Not all metals (or plastics) behave the same way. We help choose the right stock for your application, whether it’s stress-proof steel for a hydraulic component or lightweight aluminum for an aircraft bracket.

3 Programming & Setup

Our CAM programmers translate your design into efficient toolpaths. We simulate every cut before metal meets machine to avoid collisions and wasted material.

4 Machining & Inspection

Once the cycle starts, we monitor vibration, tool wear, and surface finish. After machining, parts get measured to confirm they meet spec.

5 Delivery That Works for You

Building inventory for a quarterly rollout? We’ll schedule it seamlessly.

Why Choose Us for CNC Manufacturing?

- No Job Too Tough: From micro-machining to large-scale production

- American-Made: Proudly built in our Ohio facility

- Transparent Process: You’ll know exactly where your project stands

Let’s Make Something Together

Whether you’re refining a prototype or ramping up production, we’re ready to put our CNC manufacturing expertise to work for you.