Why Choose Our Fabrication and Welding Services?

When it comes to metalwork, experience matters our shop is equipped with top-tier mills, lathes, and welding systems, allowing us to handle projects of any size or complexity. But machinery alone doesn’t guarantee quality. It’s the skill of our welders and fabricators that makes the difference.

01

Hands-On Expertise, Not Just Automation

While we use the latest equipment, we never rely on machines alone. Our team brings almost 50 years of hands-on experience to every weld and fabrication job. We know how metal behaves under heat, how to minimize distortion, and how to achieve clean, strong joints that last.

02

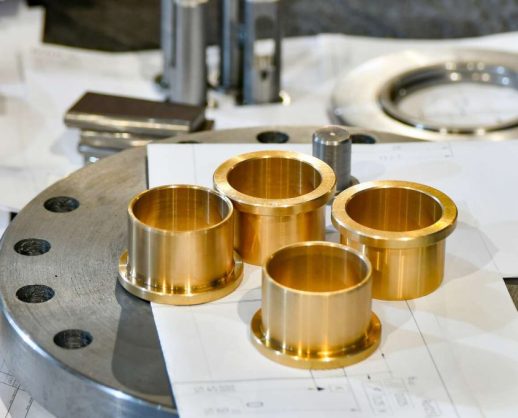

Tight Tolerances, No Guesswork

In fabrication, even minor errors can lead to big problems. That’s why we measure twice before making the final cut. Our welders and machinists work closely together to ensure that every piece fits exactly as it should. No sloppy tolerances, no mismatched parts.

03

Full-Service Capabilities

From laser cutting and CNC machining to MIG, TIG, and stick welding, we handle every step in-house. That means faster turnaround, better quality control, and a single point of contact for your entire project.

04

Made in America, Backed by Pride

We’re not just another shop. We’re craftsmen who take pride in what we build. Every weld bead, every cut edge, and every finished piece carries our name, and we wouldn’t have it any other way.

Our Equipment

At Auglaize Erie Machine, we invest in top-tier technology to deliver precision and efficiency.

Our shop features

Motoman Robotic Arc World 1000

- Fully Programmable 6-Axis Robot

- OTC Power Source

- .035 and .045 Wire Capability

- Air-Cooled Torch

- 2-Position Rotary Table

Thermal Arc Powermaster 500- P Pulse Welders Pulse Welding Carbon steel and Stainless

- 350 AMP, 100% Duty Cycle

- Compatible with .023 to .045 wire

Thermal Dynamics 100 XL Plasma Cutter

- Cuts up to 1-inch material

Motoman Robotic Welder MA 2010

- OTC Power Source

- Manual Machining Equipment & Production Saws

Materials We Master

Bring us your aluminum, stainless, or carbon steel

Industries We Serve

Our fabrication and welding work supports a wide range of industries, including:

No matter the sector, we treat every job with the same attention to detail.

Our Process

1 Understanding Your Needs

Before we touch metal, we listen. Our team reviews your blueprints, specs, and performance requirements to make sure we’re on the same page. If something doesn’t look right, we’ll speak up because catching issues early saves time and money.

2 Material Selection & Prep

Not all steel, aluminum, or alloys are created equal. We help select the right material for your application, whether it’s corrosion-resistant stainless steel for food processing or high-tensile steel for structural work.

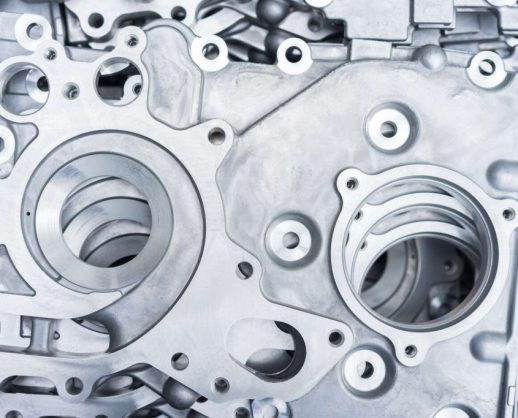

3 Precision Fabrication

Using CNC mills, press brakes, and laser cutters, we shape raw metal into exact dimensions. Every bend, hole, and contour is checked against the print before moving to welding.

4 Expert Welding

Our certified welders are great at fusing metal and creating bonds that hold up under stress. We use the correct technique for each job, whether it’s a delicate TIG weld on thin aluminum or heavy MIG welding on thick plate steel.

5 Final Inspection & Finishing

Before anything leaves our shop, it gets a thorough inspection. Dimensional checks and surface finishing (grinding, sanding, or coating) to make sure the final product meets expectations.

Let’s Build Something Together

At Auglaize Erie Machine, custom fabrication and welding is what we do best. Whether you need a single replacement part or a full production run, we’ll treat your project like our own.

Ready to get started?