What We Do for Agricultural Machinery

Farm equipment takes a beating. Plows hit rocks. Augers grind through tons of grain. Hydraulic systems cycle thousands of times. We make and repair the parts that face these challenges head-on.

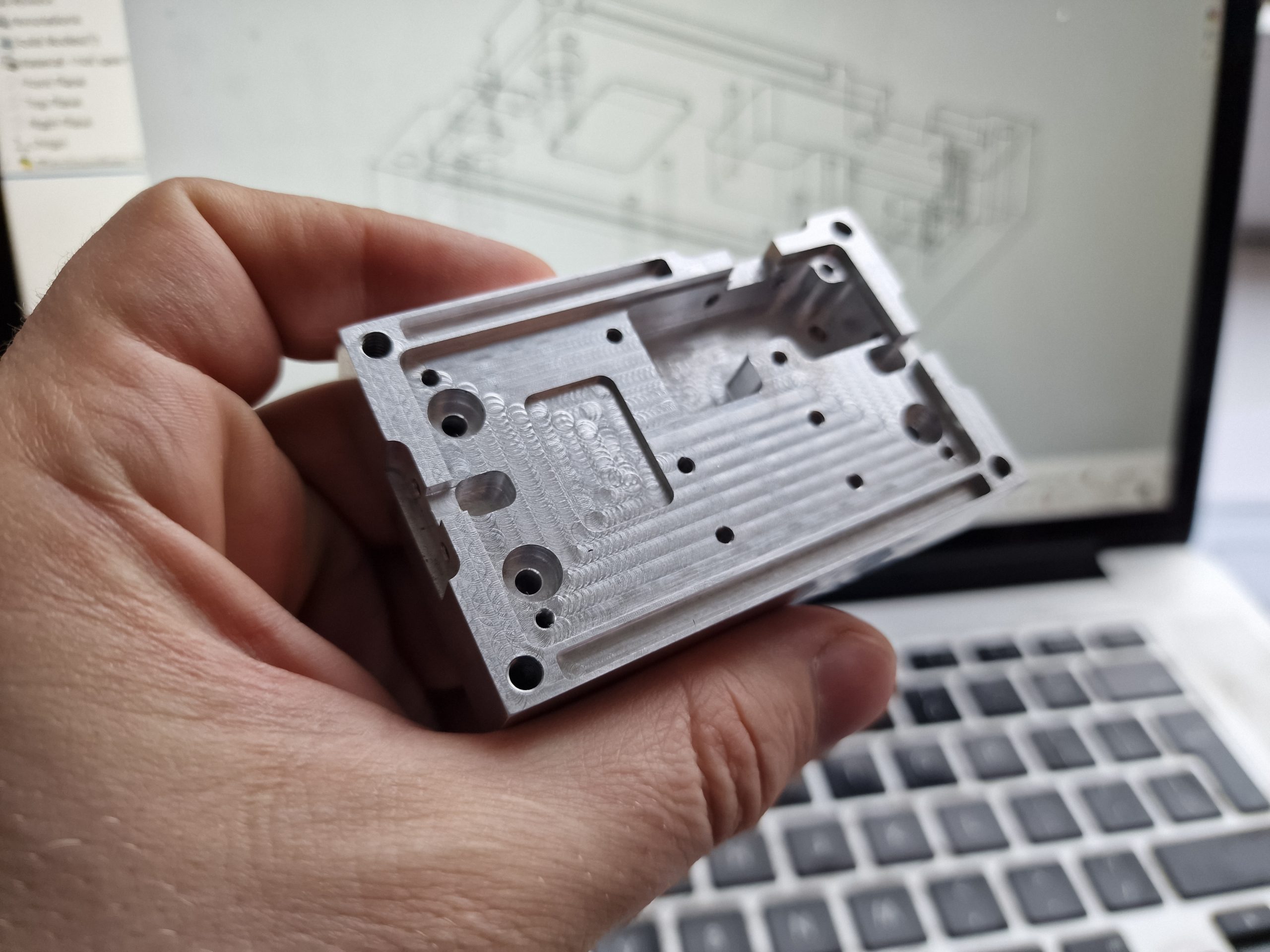

Machined Components

Our CNC lathes and mills produce:

- Shafts and bushings: Smooth, balanced, and built to handle constant rotation.

- Gears and sprockets: Cut to mesh perfectly, reducing wear and tear.

- Brackets and mounts: Designed to bear weight without bending or cracking.

Materials matter. We work with steel, stainless steel, cast iron, and abrasion-resistant alloys, whatever matches the strength needed for the job.

Fabricated Structures

Welding is where we shine. Our team builds:

- Frame reinforcements: Extra bracing for loaders, plows and trailers.

- Hoppers and chutes: Custom-sized to fit existing systems.

- Guard plates and covers: Protection for belts, chains and moving parts.

With robotic and manual welding, we provide deep, clean joins that won’t fail under stress.

Repairs That Save Time and Money

Broken part? Don’t replace the whole assembly. We can often:

- Re-machine worn surfaces: Restoring seals and fits.

- Recreate discontinued parts: No need to hunt for old inventory.

- Add protective coatings: Like zinc plating or powder coating to fight rust.

Why Farmers and Equipment Dealers Choose Us

1 We Know Farming’s Demands

Agricultural machinery doesn’t get gentle use. Parts must resist dirt, moisture, vibration, and heavy loads. We select materials and designs that do just that.

2 Fast Turnaround When It Counts

Breakdowns cost money. When you need a replacement ASAP, our team prioritizes urgent jobs without cutting corners.

3 No Guesswork, Just Good Fits

Tolerances matter. A bushing that’s a thousandth of an inch off can cause downtime. Our machines hold tight specs, so parts drop into place—no hammering or forcing.

Materials Built for the Field

We work with what lasts:

- Cold-rolled steel: Tough and cost-effective for structural parts.

- Stainless steel: For components exposed to moisture and chemicals.

- Hardened alloys: Where abrasion resistance is key.

- Aluminum: When weight savings matter without sacrificing strength.

Need a finish? Options like powder coating or chrome plating add extra protection against the elements.

From Small Farms to Large Operations

We’ve helped:

- Family farms: Fixing decades-old equipment to keep it running.

- Equipment manufacturers: Prototyping new designs or fulfilling production orders.

- Repair shops: Supplying hard-to-find replacements quickly.

No job is too small or too specialized. If it’s metal and it’s part of agricultural machinery, we can make it.

Let’s Get Your Equipment Back to Work

Fields don’t wait and neither should you. Whether you need a one-off repair or a batch of custom parts, we’ll deliver quality that meets the demands of farming.